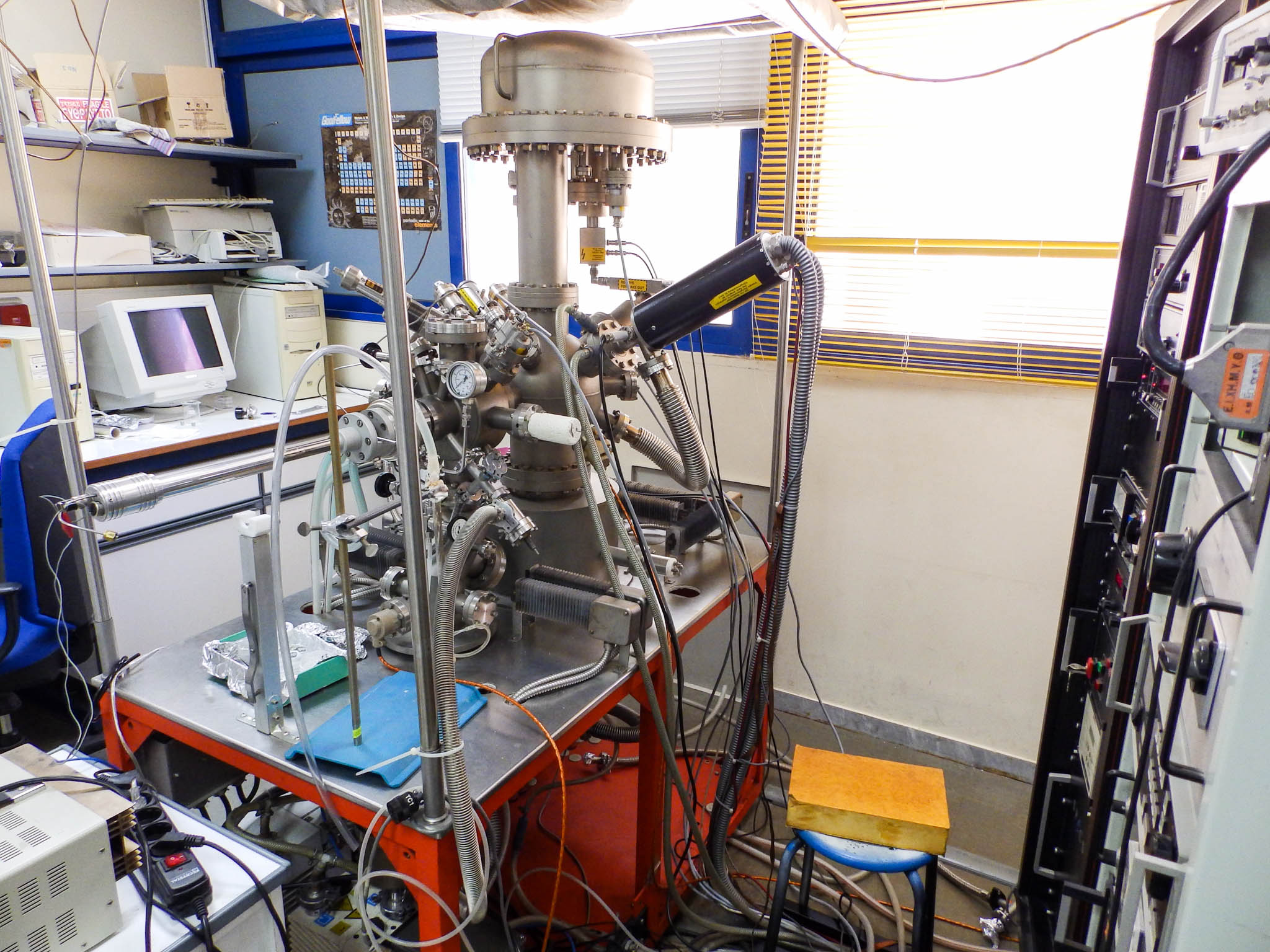

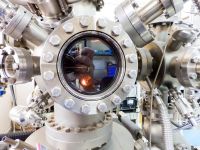

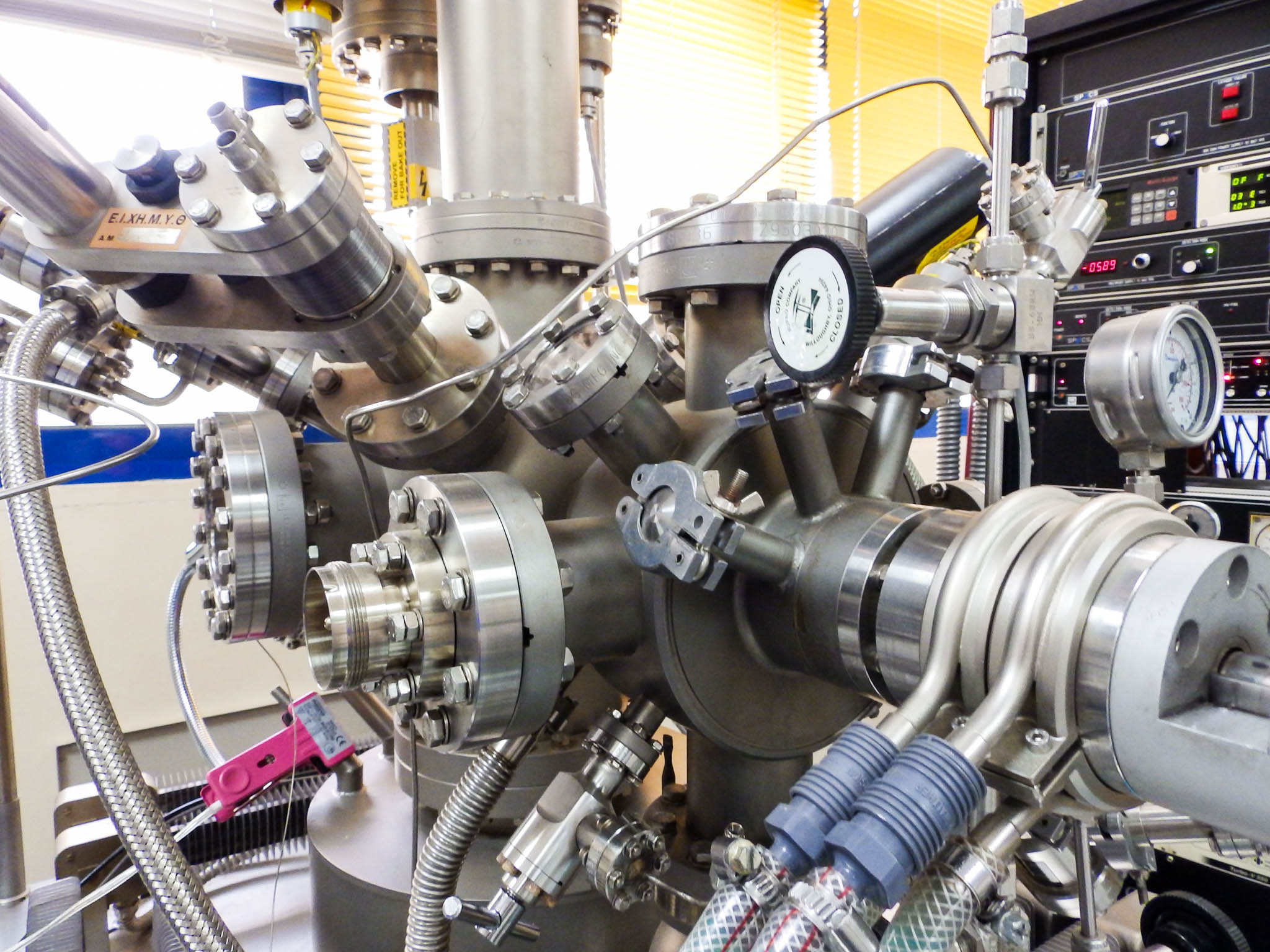

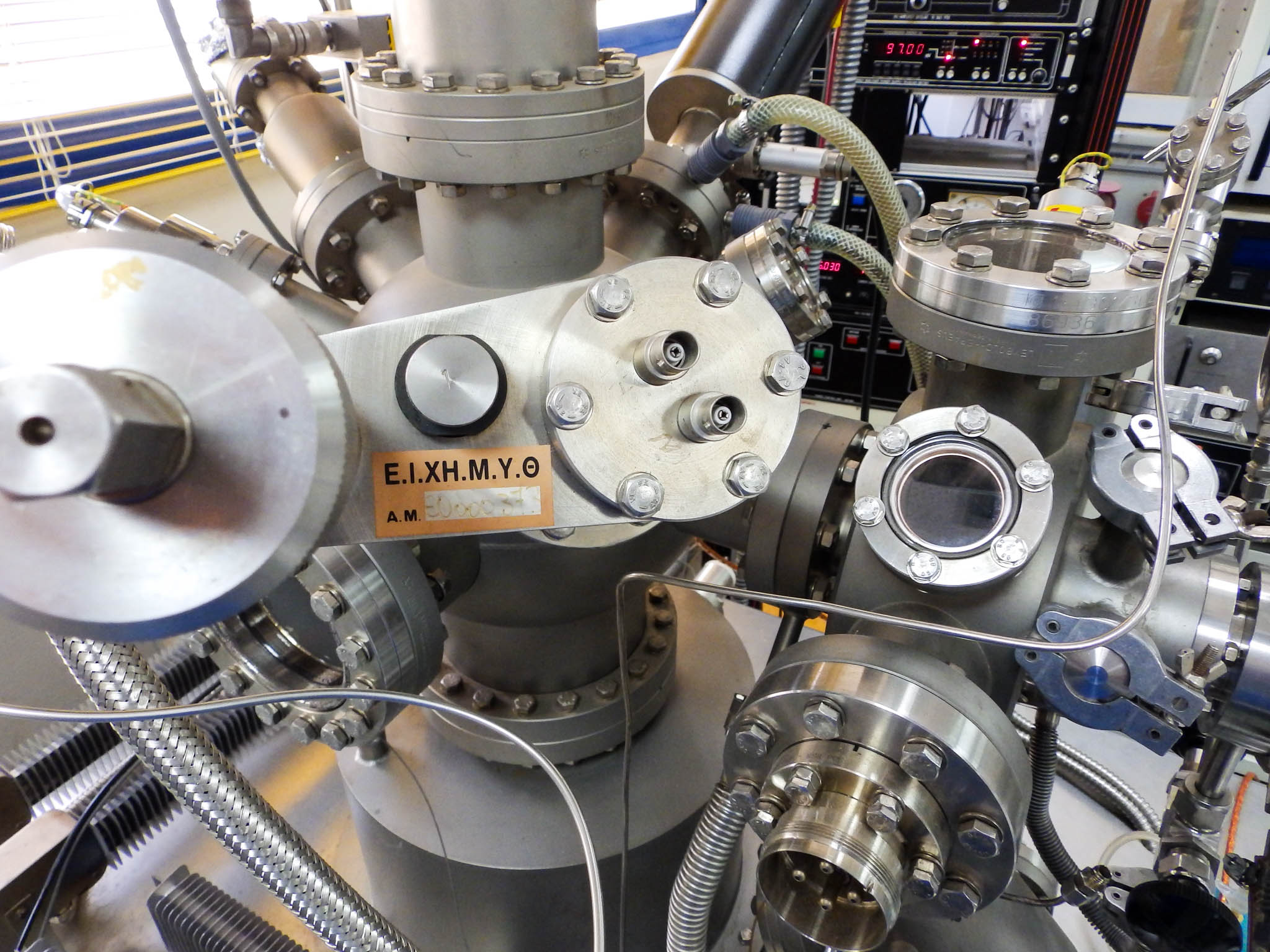

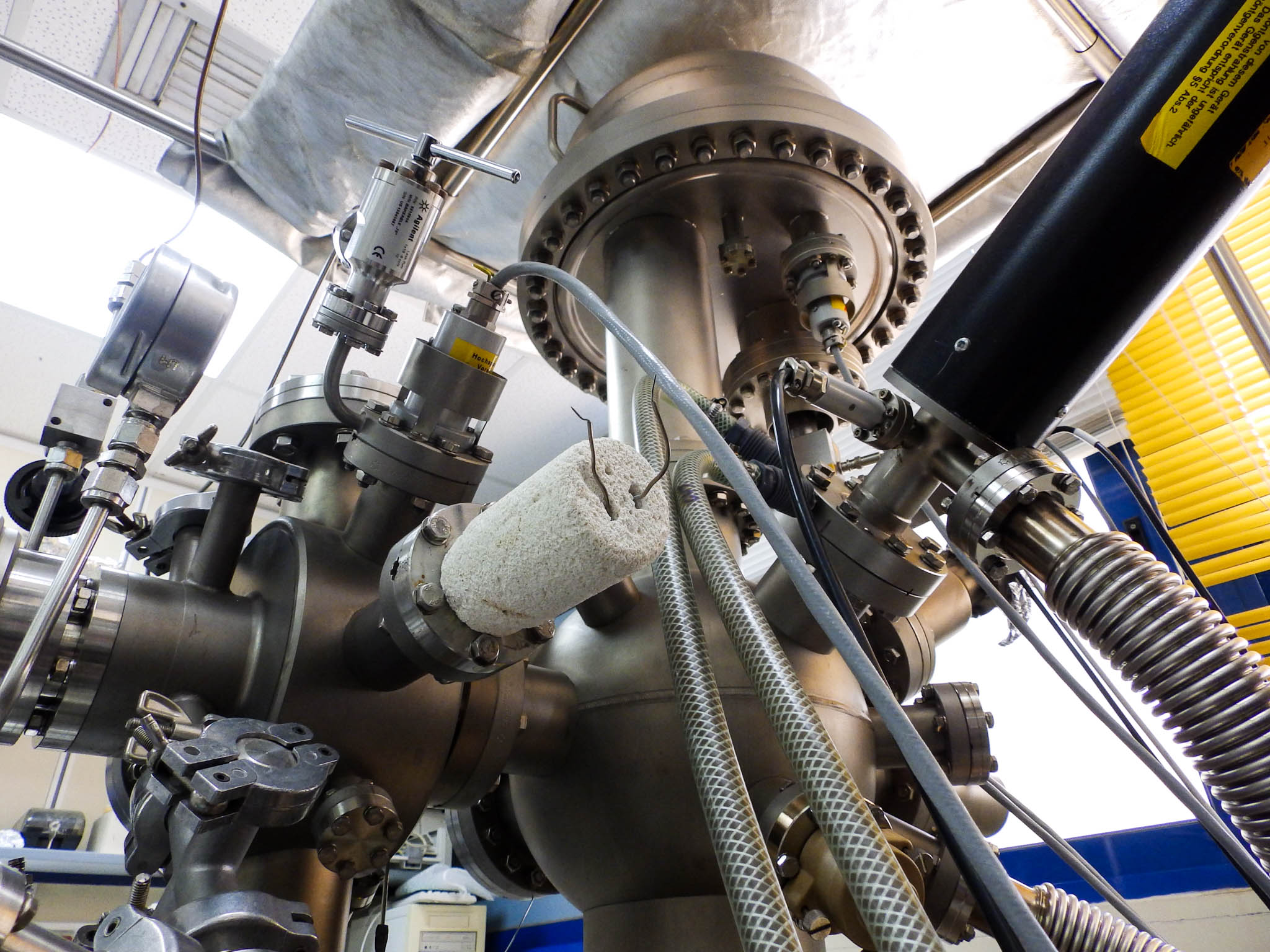

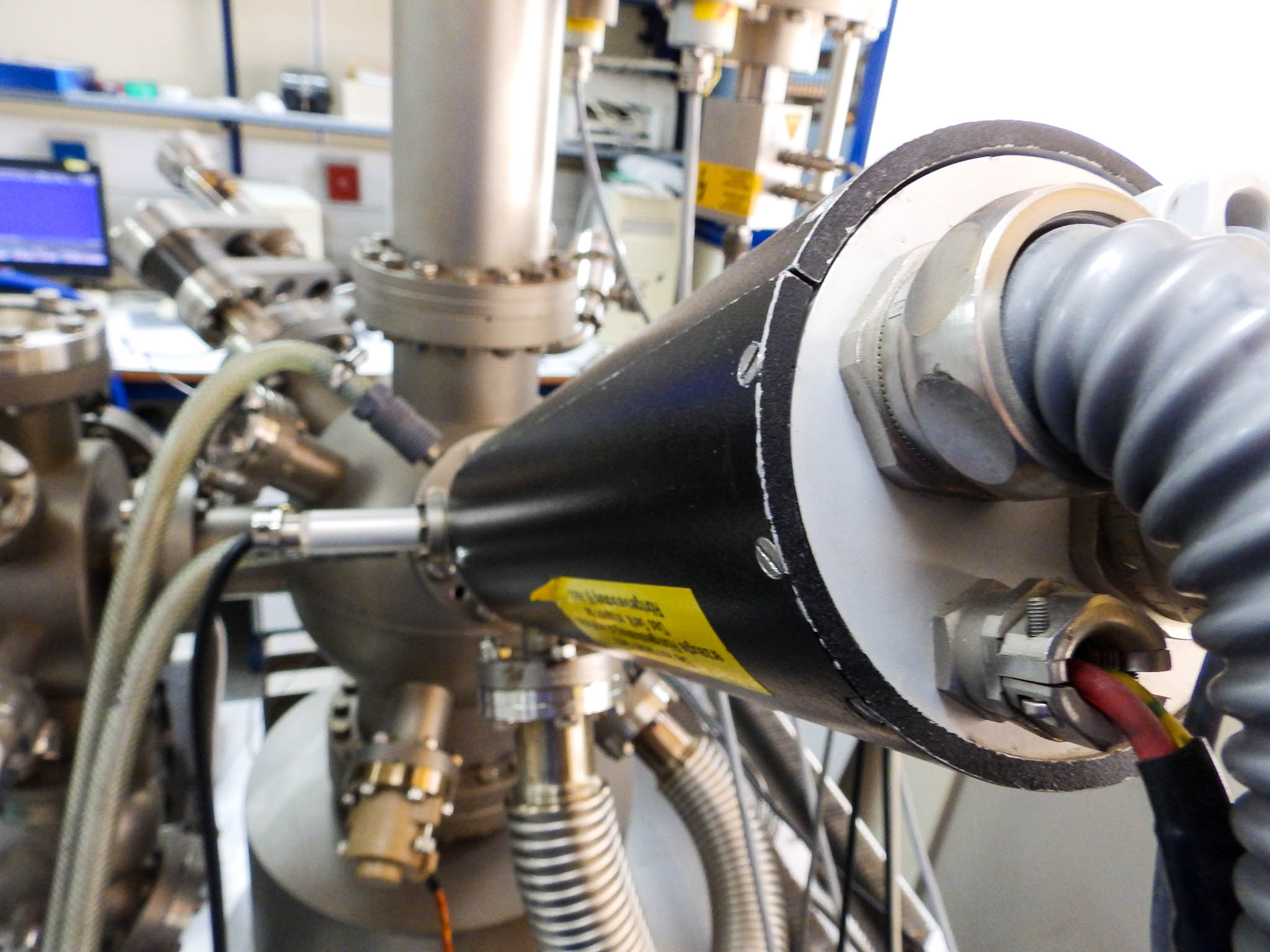

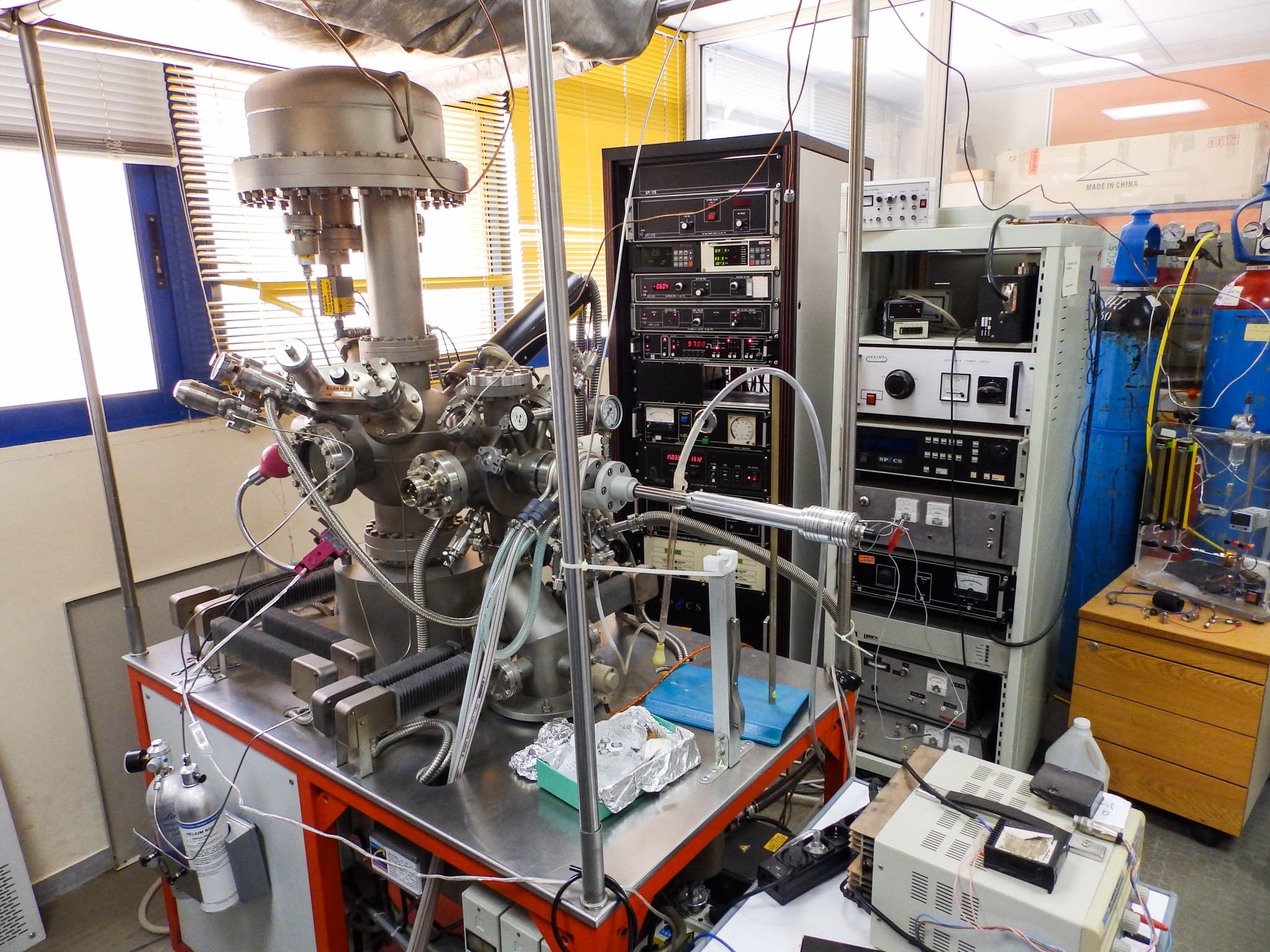

Ultra High Vacuum System

Surface characterization techniques: XPS/ UPS/ EELS

X-ray photoelectron spectroscopy (XPS) is a surface analysis technique capable of providing elemental and chemical state information from the outer 5 to 12 nanometres of a solid surface. All elements can be detected with detection limits in the 0.1 to 0.5 atomic percent.

Similar with XPS, Ultra violet photoelectron spectroscopy (UPS), using UV radiation (with photon energy of 10-45 eV) examine valence levels. The Work function of the materials and the Ionization Potential of an organic material can be determined. The information depth is ~3nm.

By stepwise deposition of a material onto a substrate the determination of the energy level alignment at the interface that is the appearance of an interface dipole or the level bending effects can be determined by XPS/UPS techniques.

Electron energy-loss spectroscopy (EELS) is a surface analytical technique that measures the change in kinetic energy of electrons after they have interacted with a specimen. The low-loss or valence region of an EEL spectrum (< 50 eV) provides valuable information about the band structure and in particular about the dielectric properties of a material (e.g., band gap, surface plasmons). The information depth is ~3nm.

Moreover, the Ultra High Vacumm chamber is equipped with: (a) Ion gun for sputtering the surfaces (for contamination removal) and for controllable induce defects onto graphene sheets, (b) a stainless steel sample holder able to be heated

up to 650 °C in order to thermal reduction of oxides, GO, e.t.c. (c) gas inlet systems in order to surface exposure under various gases and controllable pressures ranging from 10-6mbar up to 1bar.

Ex.1: The graphene surfaces was modified byIon beam (Ar+) bombardment with various energies in order to controllable induce defects. The effect of the defects on the adhesion of PMMA/graphene interfaces was studied. The density of defects on graphene increases as the irradiation dose increases caused the adhesion improved of graphene/PMMA interface.

Ex.2: Chemical modification of GO thin films on ITO was investigated. The absolute Work Function (WF) variation with the oxygen content (by thermal reduction of GO) and the heteroatom concentration (nitrogen) was experimentally recorded. The graphitic assemblies were reduced with either thermal (annealing in ultrahigh vacuum (UHV)) or chemical (hydrazine-induced) treatment. Also, a combination of both processes was studied. The WF of rGO thin depends on multiple parameters such as the heteroatom concentration, the thickness, the GO flake size, and speciation. It has provided valuable information for designing materials with fine-tuned electronic and chemical properties for the optimization of device performance.

WP4 Failure processes of graphene in tension and compression

Project Summary

Ar+ ion bombardment as a tool for controllable defect induction to single layer graphene

The scope of this work-package is the creation of defects in graphene created with a controllable manner, by Ar+ irradiation, and to avoid the defects oxidation in the atmosphere. For this purpose CVD monolayer graphene on Cu samples were subjected to Ar ions with different energies in ultra-high vacuum (UHV) chamber and subsequently the defected samples were exposed to H2.

The defects creation with Ar+ gun was performed in Ultra High Vacuum System (UHV). The H2 exposure was performed in the high pressure cell directly attached to the UHV chamber. The investigation was performed with surface sensitive techniques, X-Ray Ultra Violet photoelectron and electron Spectroscopies ( XPS-UPS-EELS) and with Raman.