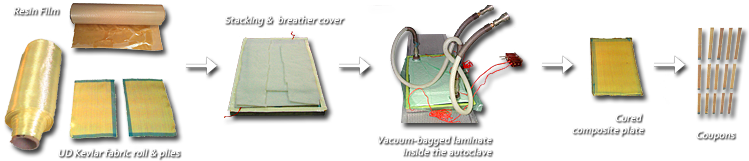

Autoclave processing of polymer- and epoxy- matrix composites

Our semi-industrial autoclave by Aeroform Limited (Poole, UK) can run simultaneous temperature/pressure/vacuum profiles within the ranges of 25 to 225°C and -1 to 10 Bar. We use the chamber to cure mainly polymer- and epoxy-matrix composites, custom laminates (eg with embedded SMA actuators) and nanocomposite materials (eg buckypapers). The autoclave's pressurized environment is also used in investigating watertightness of submersed structures. Manufacturing possibilities include Resin Film Infusion (RFI), Vacuum Bagging, Resin Transfer Infusion (RTI), Prepreg, and Wet/Hand-layup.

Researchers involved:

• Konstantinos Dassios

• Dimitris Kastanis

• Georgia Tsoukleri

• George Trakakis

Relevant Publications:

- "Effect of Processing and Loading Conditions Upon the Fatigue Behavior of A Cf/Epoxy Laminate" by C. Koimtzoglou, K. Dassios and Costas Galiotis (Submitted for Publication)

- "Effect of Fatigue on the Interface Integrity of Unidirectional Cf-Reinforced Epoxy Resin Composites" by C. Koimtzoglou, K.Dassios and C. Galiotis , Acta Materialia (2009), doi:10.1016/j.actamat.2009.02.038 Download the paper (pdf)

- “Stress generation by shape memory alloy wires embedded in polymer composites” by D.Bollas, P.Pappas, J.Parthenios and C.Galiotis, Acta materialia, 55/16, 5489-5499 (2007) Download the paper (pdf)