Laser Raman Miscoscopy for fibre stress measurements at the microscale

- Published in Research

- Written by Super User

- Be the first to comment!

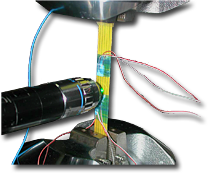

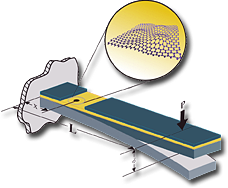

Laser Raman Microscopy (LRM) is the only experimental technique able to measure stress or strain on individual fibres at the microscopic level. The Raman wavenumbers of certain vibrational modes of crystalline materials – such as carbon, SiC or Kevlar fibres embedded in composites – are stress/strain dependent, most frequently through a simple linear relation that can be established experimentally and constitutes the fibre-specific Raman Calibration Curve (RCC). The RCC of a fibre can be used reversely to translate shifts captured from the same type of fibre in a composite material, to stress/strain.

Laser Raman Microscopy (LRM) is the only experimental technique able to measure stress or strain on individual fibres at the microscopic level. The Raman wavenumbers of certain vibrational modes of crystalline materials – such as carbon, SiC or Kevlar fibres embedded in composites – are stress/strain dependent, most frequently through a simple linear relation that can be established experimentally and constitutes the fibre-specific Raman Calibration Curve (RCC). The RCC of a fibre can be used reversely to translate shifts captured from the same type of fibre in a composite material, to stress/strain.

A multifunctional composite without insertion of actuators can be developed by exploiting the

A multifunctional composite without insertion of actuators can be developed by exploiting the  Modern technologies need

Modern technologies need  The integration of

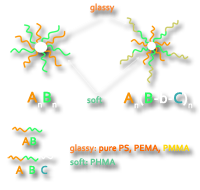

The integration of  Block copolymers are excellent candidates for a

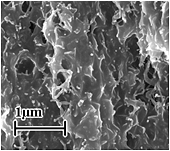

Block copolymers are excellent candidates for a  Free-standing paper-like or foil-like materials based on modifications of elemental carbon draw a great attention over the last years. Their proposed or already implemented uses include protective layers, chemical filters, components of electrical batteries or supercapacitors, adhesive layers, electronic or optoelectronic components, and molecular storage. Similarly to

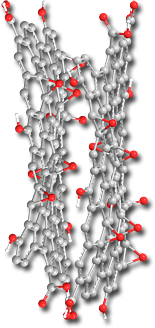

Free-standing paper-like or foil-like materials based on modifications of elemental carbon draw a great attention over the last years. Their proposed or already implemented uses include protective layers, chemical filters, components of electrical batteries or supercapacitors, adhesive layers, electronic or optoelectronic components, and molecular storage. Similarly to  Graphene is a two-dimensional crystal, consisting of

Graphene is a two-dimensional crystal, consisting of  The classic methods for low volume fraction polymer nanocomposites based on CNTs involve melt blending, solution casting, solution mixing, direct mixing and in-situ polymerization. However, using these techniques has resulted in phase separation between polymer and CNTs, low polymer wetting of CNTs and low interfacial shear strength between polymer matrix and CNTs.

The classic methods for low volume fraction polymer nanocomposites based on CNTs involve melt blending, solution casting, solution mixing, direct mixing and in-situ polymerization. However, using these techniques has resulted in phase separation between polymer and CNTs, low polymer wetting of CNTs and low interfacial shear strength between polymer matrix and CNTs. Carbon nanotubes (CNTs)

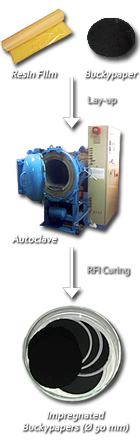

Carbon nanotubes (CNTs) The production of high volume fraction CNT films and tapes, the so called

The production of high volume fraction CNT films and tapes, the so called  We grow

We grow